Americans throw out 40% of food each year despite the fact that 1 in 6 of us do not know where our next meal will come from. In this project, I co-developed a complete package of solutions to address food waste in warehouse settings with a proven food waste reduction rate of 57%.

Subjects:

Integrated Product Development (IPD)

Food Waste

Inventory Management

Key contributions:

User Research

Product Design

Business Strategy

How long can food last?

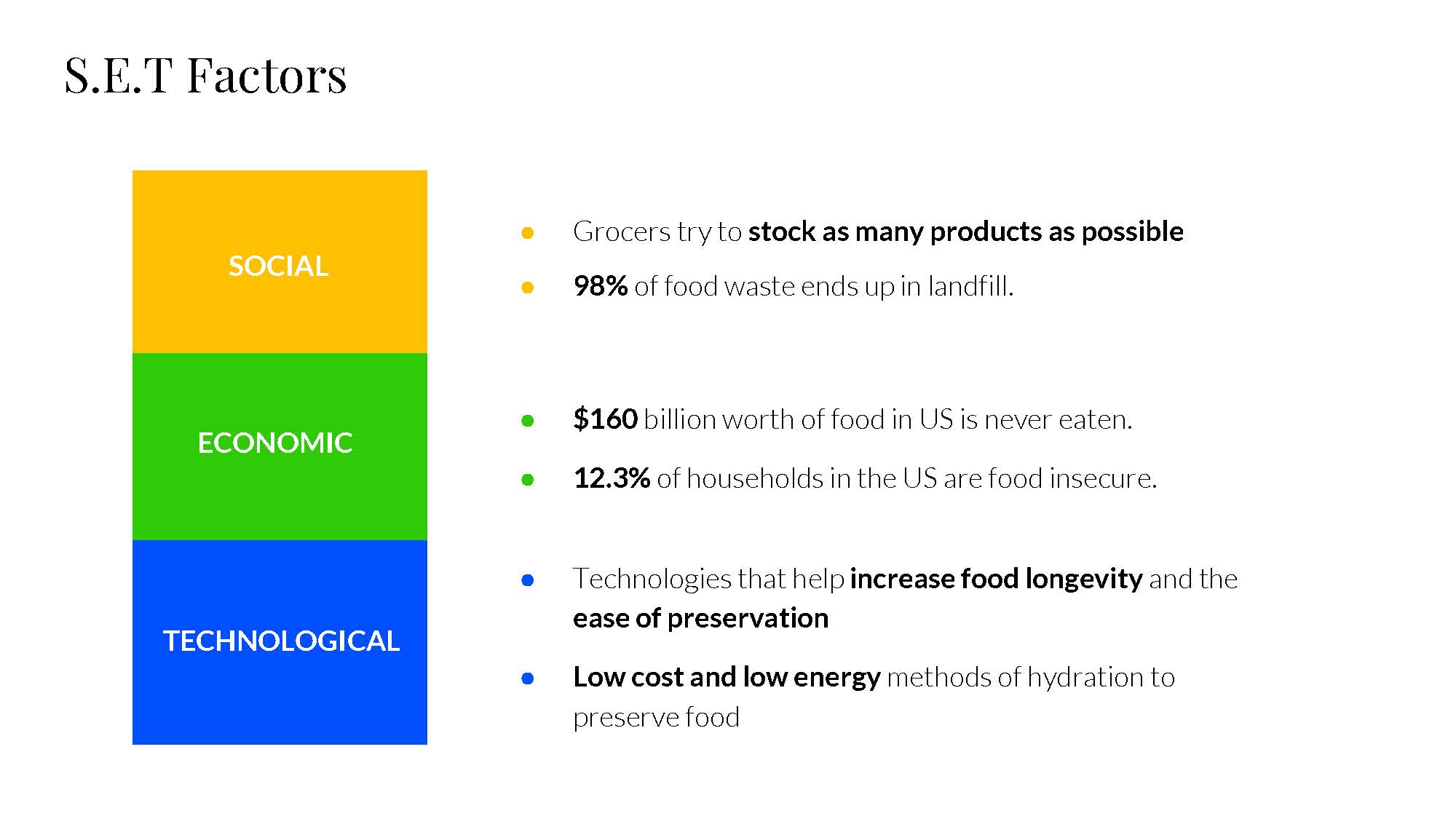

Being one of the largest agricultural exporting countries, a staggering number of people in the US do not have access to reliable and variable affordable nutrition. Yet “in the United States, food waste levels serve as dominant components of landfill masses, oil and freshwater waste, methane and CO2 emissions, damage to wildlife ecosystems, and substantial financial losses.”

I have been challenged in my master’s capstone project to research food waste with a focus on distribution centers. The goal is to identify ways to reduce waste and to assemble a genuine, viable system that improves the food shelf life.

Secondary Research

To better understand the problem, I began by reviewing the literature and identifying factors contributing to food waste. Food waste is such a huge concept and I didn't want to boil the ocean. The research allowed my team to determine where we could make the most impact within a reasonable scope.

The research shows that produce preservation in logistics is the key to as it was the main source we found that contributes to food waste. the project sponsor, Mark Zimmerman from Revittle, suggested that we conduct further research throughout the food supply chain to understand how different food products are packed, shipped, stored, and inspected, to identify opportunities.

Primary Research

The team paid a number of visits to stakeholders that ranges the entire food supply chain, covering producers, distributors, retail grocery stores, and food rescue groups, such as:

Toigo Farms: Organic greenhouse grower

Ahold Delhaize (Giant-Carlisle): One of the largest food distributors in Pennsylvania

Restaurant Depot: Pittsburgh local distributor/wholesale grocery store

Safran’s Supermarket: supermarket located in Pittsburgh

412 Food Rescue: Local food rescue organization

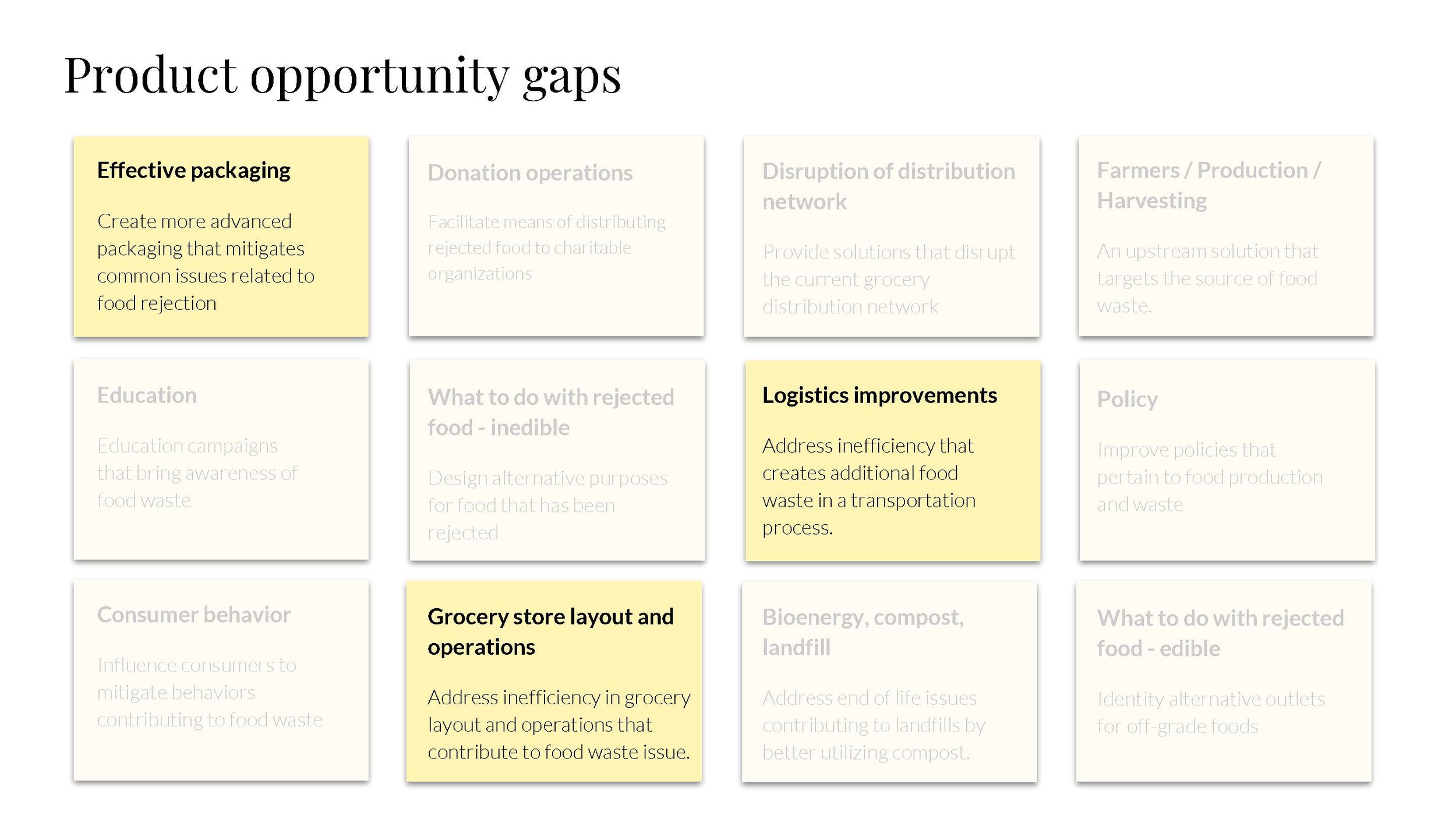

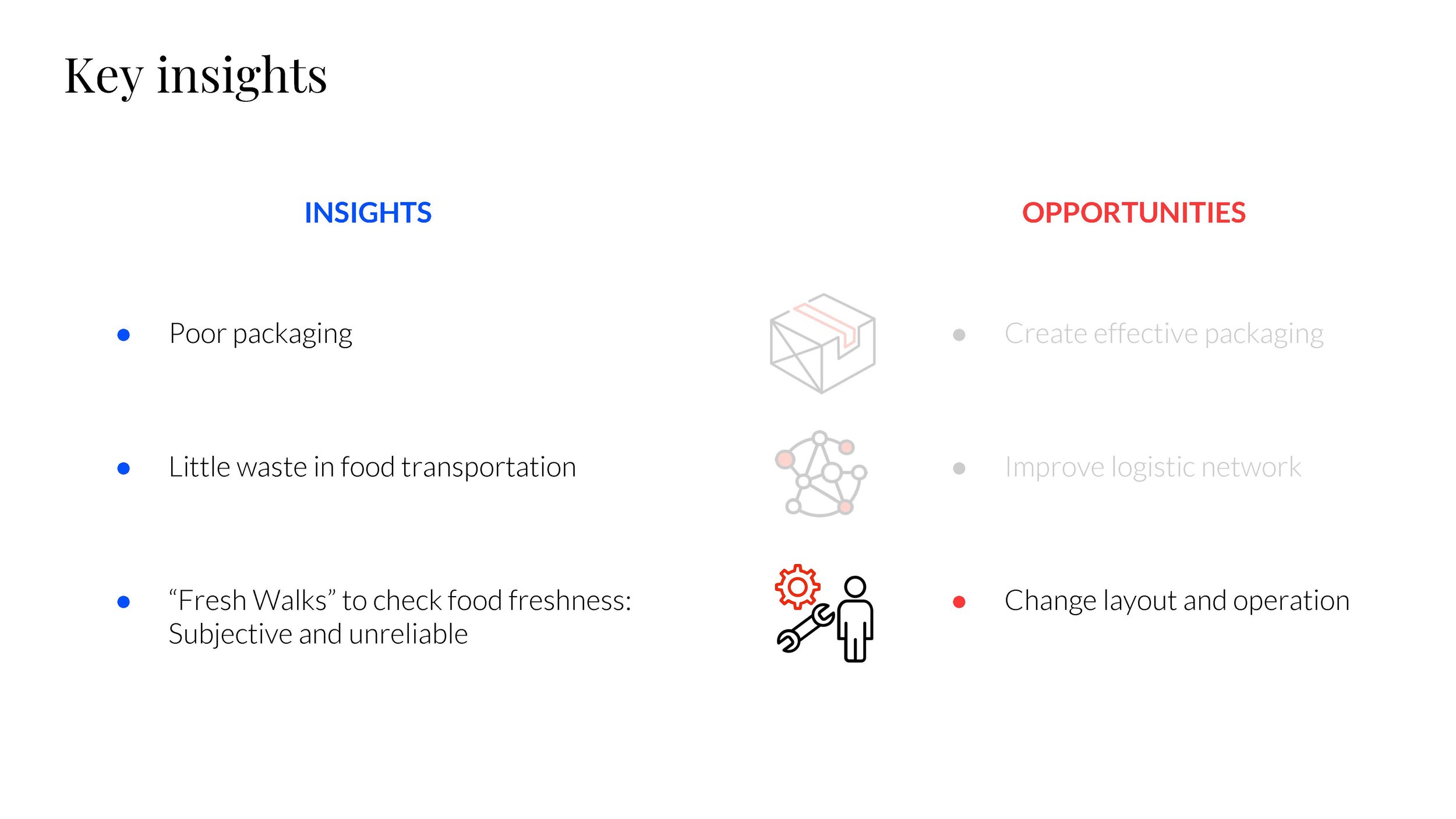

The primary research provided greater clarity on the scope, impact, and challenges as we learned that food waste was the result of both external and internal factors.

External factors: Low protection packaging and the subjective “fresh walk” (meaning a person literally walks across the aisles of a warehouse to identify produce that’s gone bad and threw them away).

The internal factor: The turnover rate of food against its shelf life

I suggested removing the packaging-related opportunity because it’s low business opportunities due to extremely low margin. Therefore, we honed in on 2 specific opportunities:

Opportunity 1: Better identify the freshness of food compared with the current subjective checking process of fresh walks.

Opportunity 2: Extend the shelf life through better storage and preservation methods to prevent products from spoiling.

Reviewing these opportunities led to a single, revised Product Opportunity Gap (POG): Improve aspects of inventory management pertaining to identification, storage, and preservation of food throughout its selling cycle.

Making Fresh’n Easy

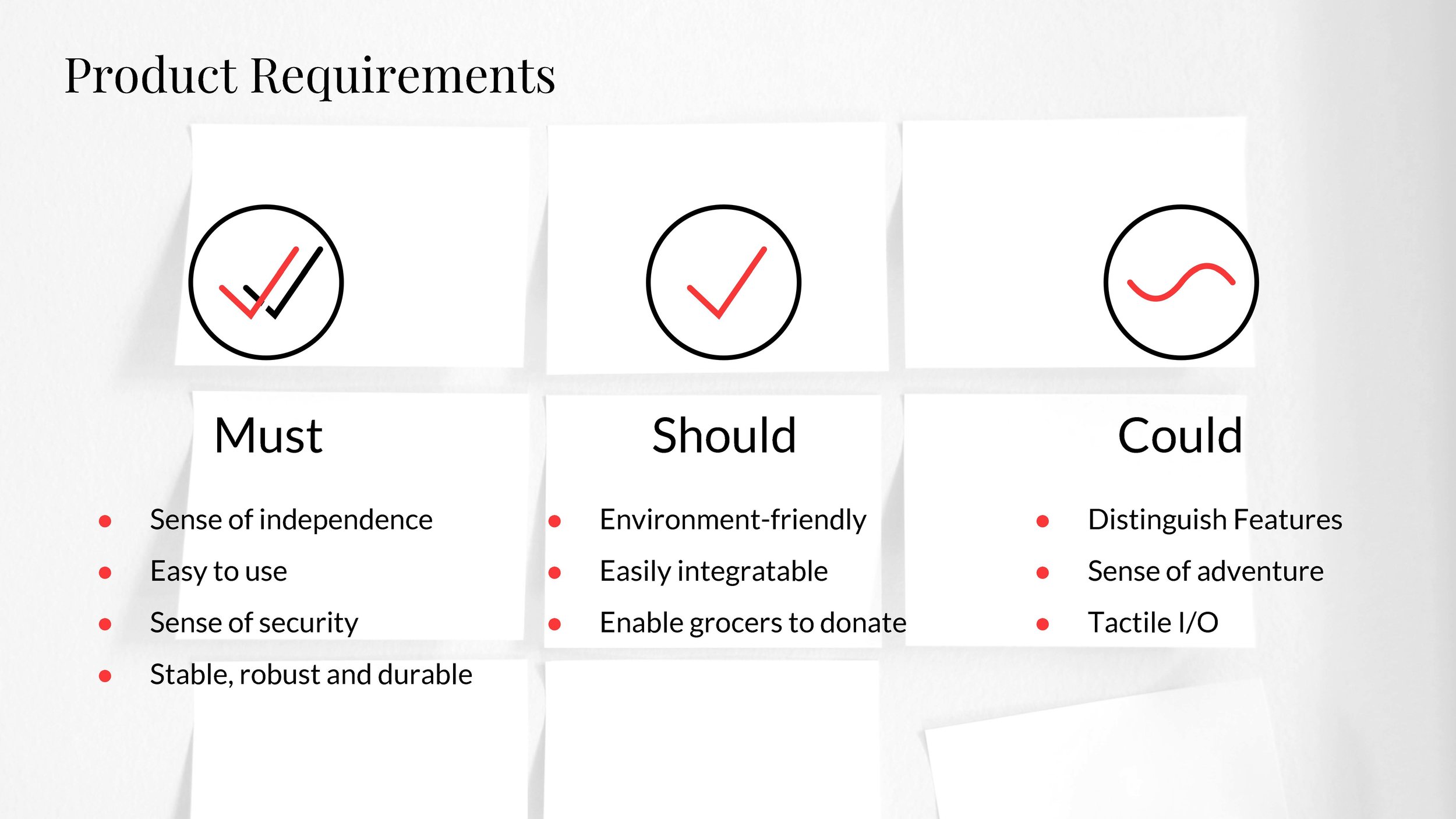

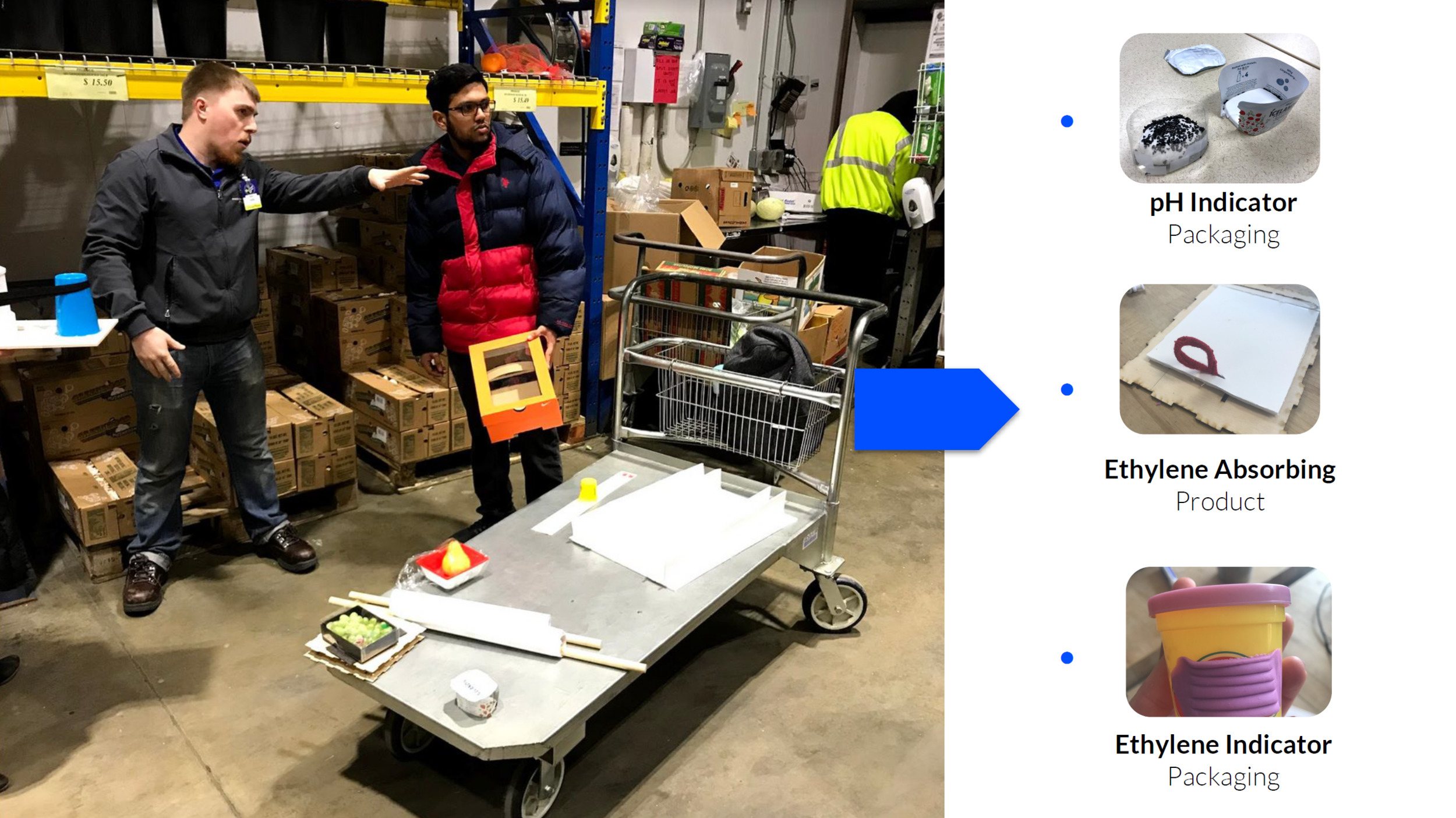

The team started generating as many concepts as possible, focusing on quantity to the maximum inspiration. We partnered with Ian McPherson, one of the produce section inventory managers at Restaurant Depot, and Christine Gallagher from Ahold Delhaize, who offered us real warehouses for concept testing and insightful feedback.

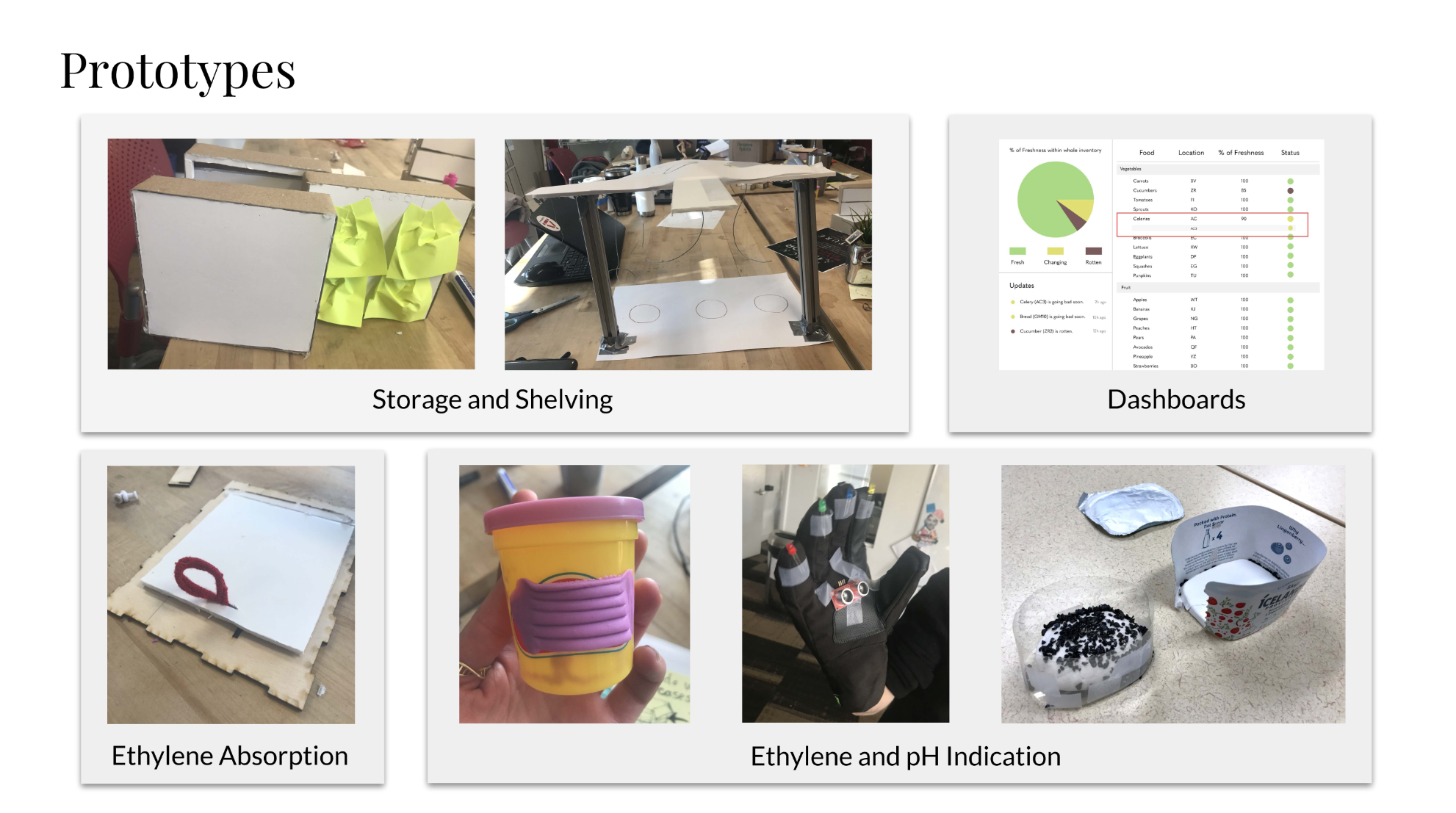

Two concepts emerged from a number of ideas the team generated and prototyped

Concept 1 - Ethylene absorption: An overhead shield or an ethylene pad either within or beneath the pallet

Concept 2 - pH indicator: To provide clear visual signals for the freshness of dairy products

A decision Matrix was developed to assist our concept selection:

| Criterion | Definition | Weight |

| (1 Low - 5 High) | ||

| Designing for Users | Does it satisfy the must-haves/should haves from our stakeholder research? | 5 |

| Initial Sponsor and Stakeholder Interest | Feedback from Mark, Marlin, Restaurant Depot, Ahold-Delhaize D.C. | 3 |

| Technologically Feasible? | 5 = no technology/easy-to-show-that-it-works technology | 5 |

| Economic Viability (prediction) | Favor concepts with lower implementation costs if they all reduce waste | 3 |

| Phase 4 Feasibility (time and cost constraints) | 5 = few unique or costly parts to consider for plan/prototype | 5 |

| Ease of Implementation | 5 = minimal number of changes required or changes are minor | 3 |

| Scalability | If successful in a pilot program, 5 = just make more of them | 3 |

| Team Member Interest | Put this last in case thinking about the others provides a more informed decision | 5 |

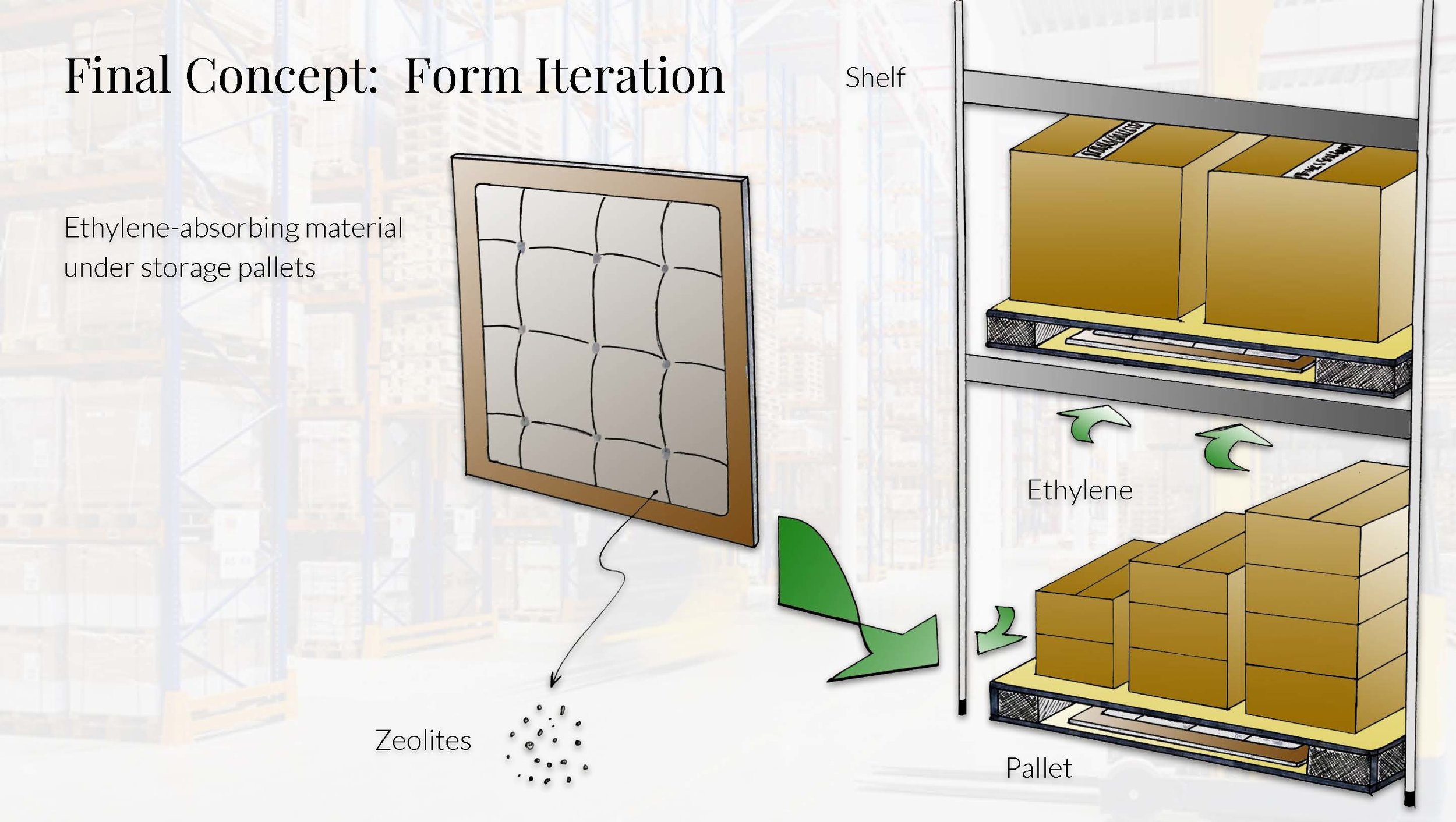

Based on the user feedback received, literature research, and the results of the decision matrix, the team believed that a zeolite-based ethylene absorption product is the most innovative and cost-effective solution that both warehouses and grocery stores are able implements to keep produce fresh, especially for perishable items such as strawberries, bananas, mushrooms, and avocados.

Proof-of-Concept

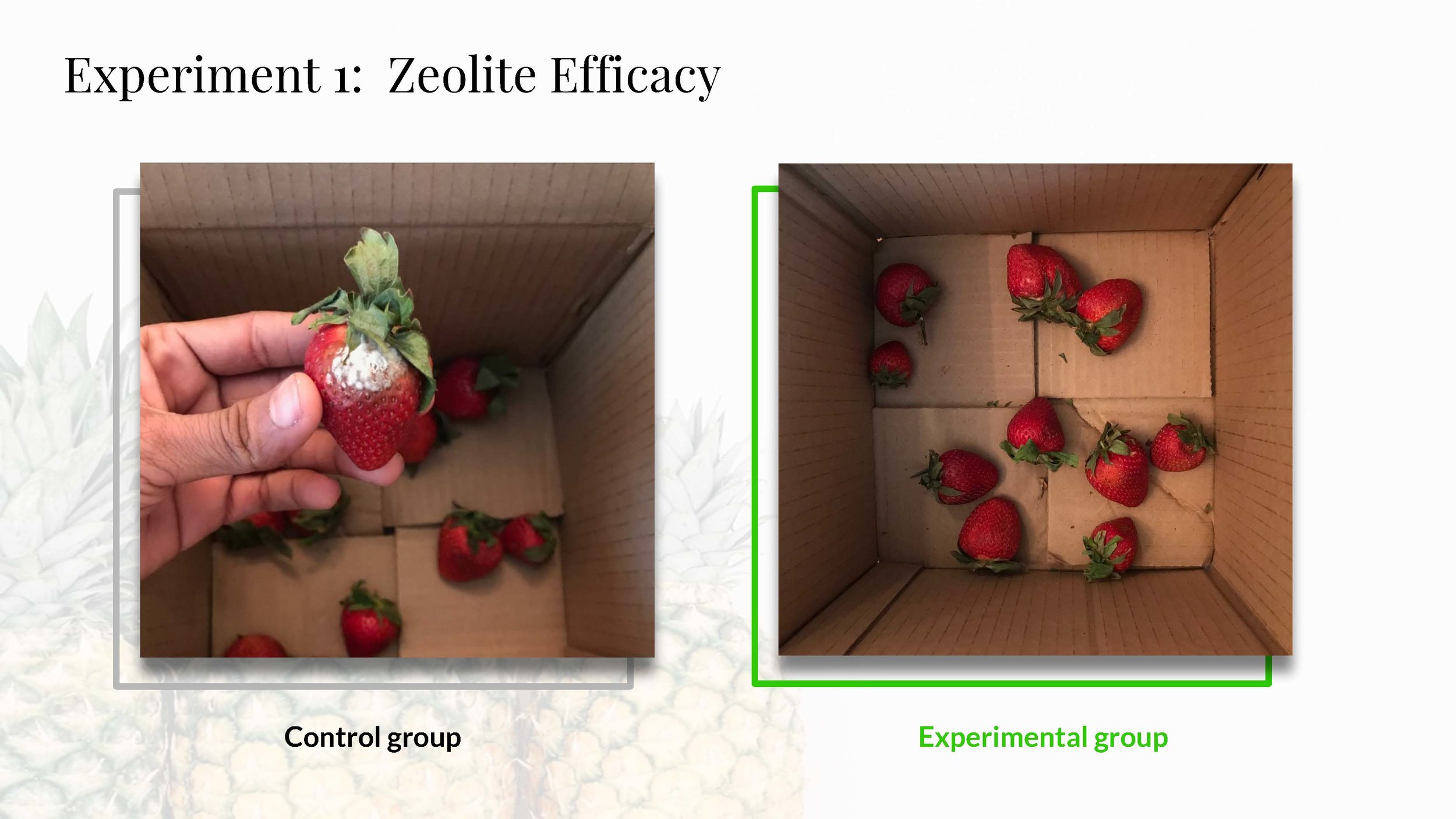

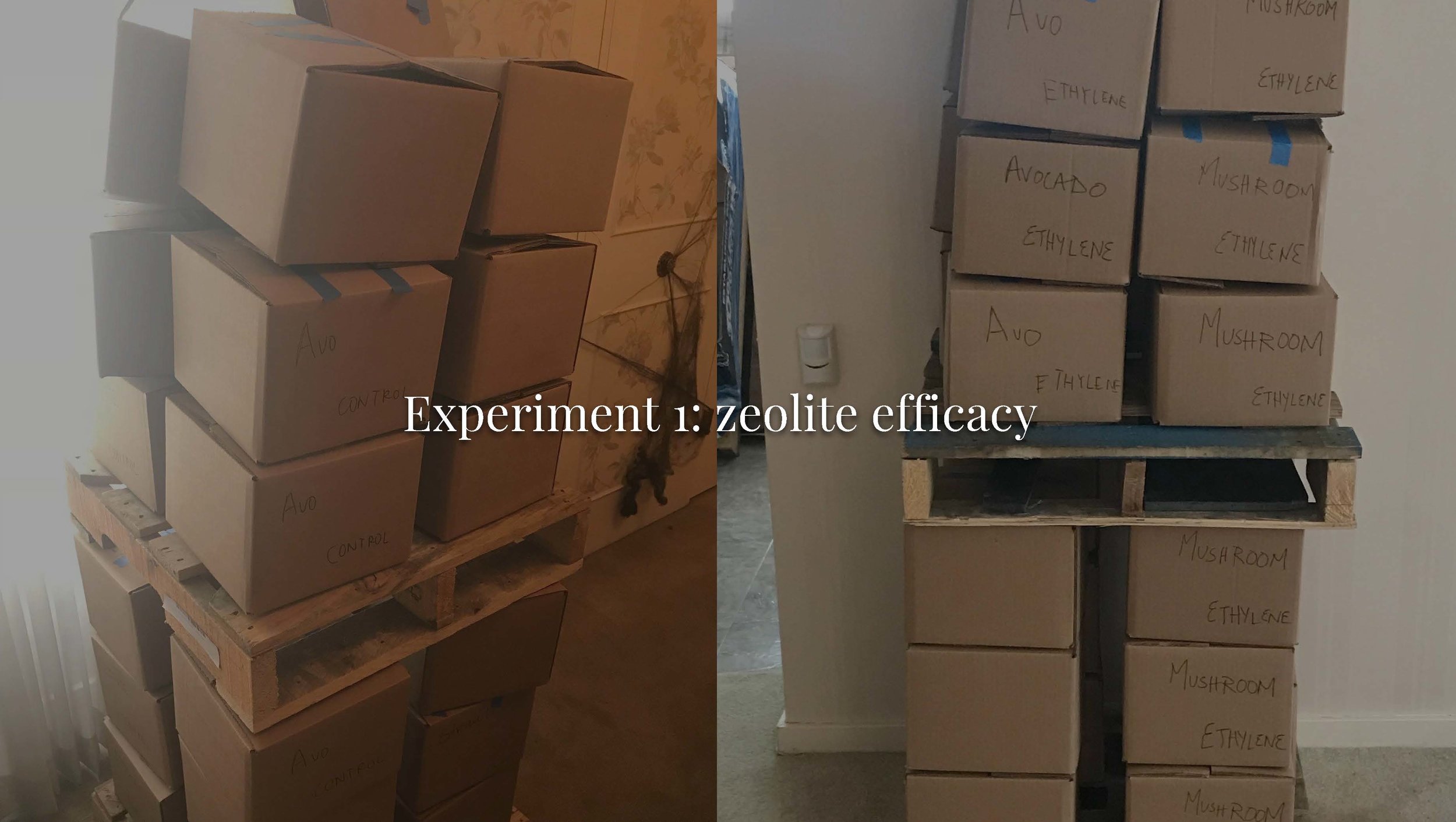

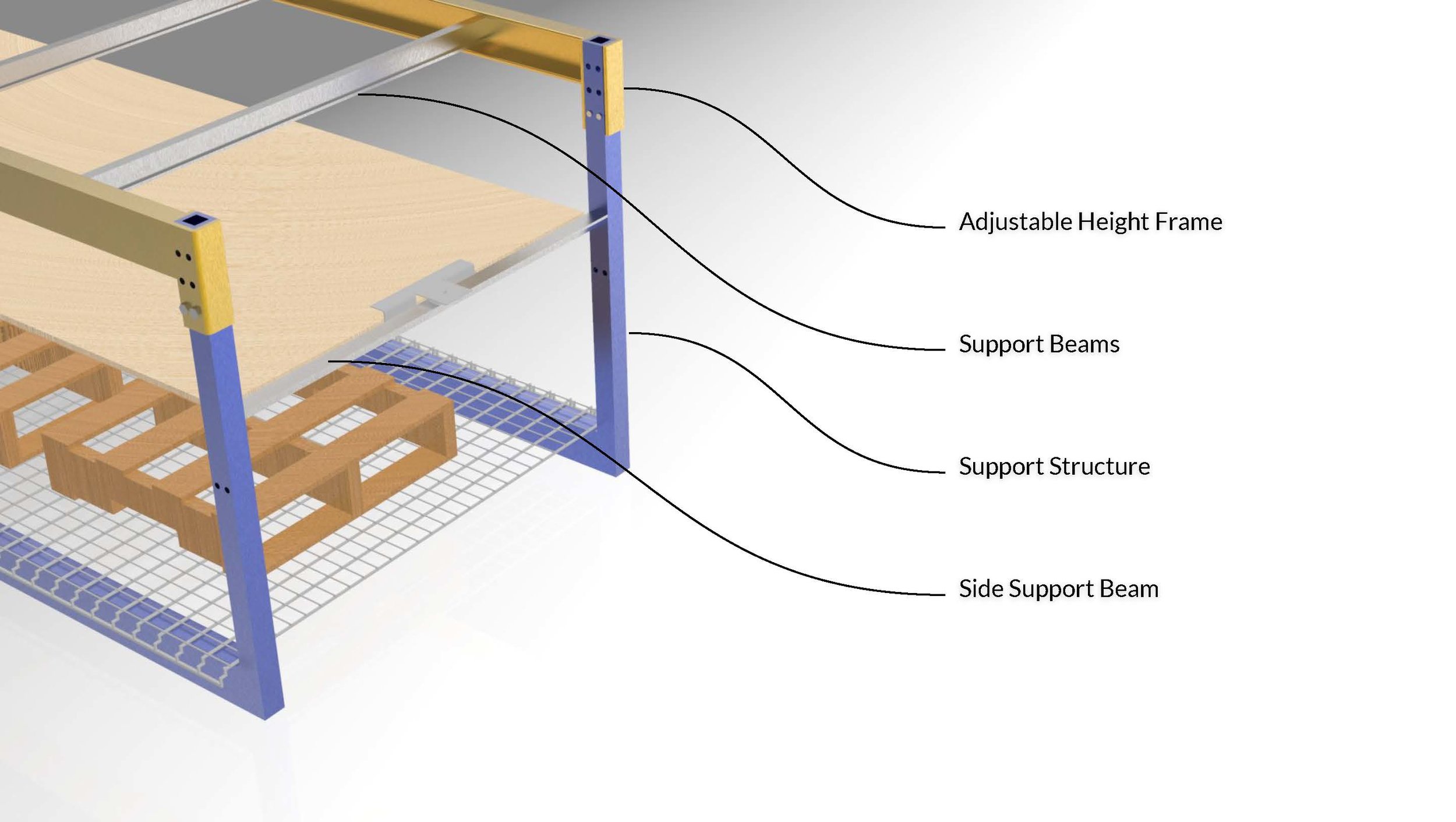

To confirm the feasibility of the solution, I developed a proof-of-concept that represents the shelving system at the warehouses. For this experiment, there were two pallet racks, each with stacks of three crates of food containing strawberries, avocados, lettuce, and mushrooms.

Control group: No zeolites

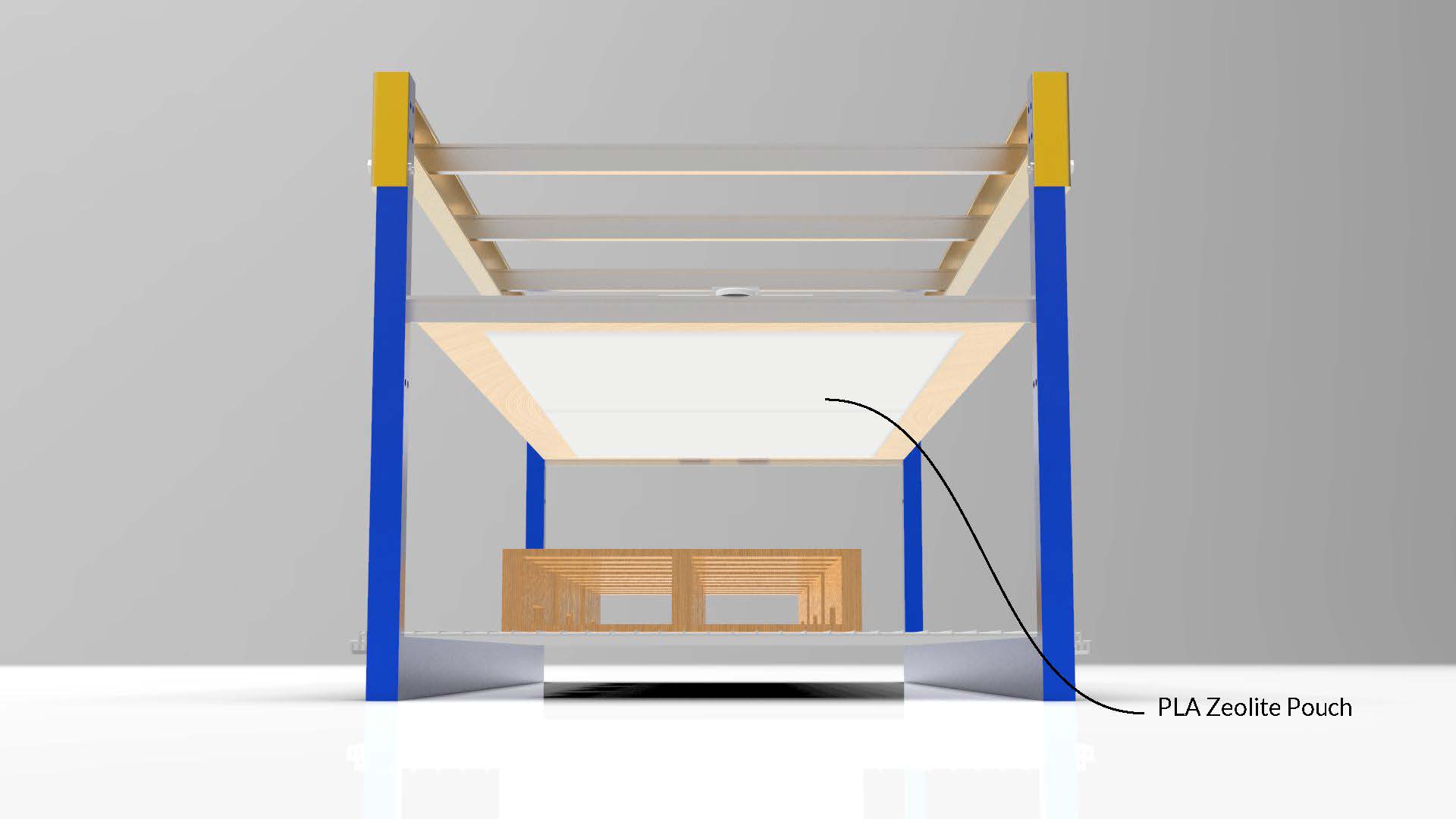

Experiment group: Locally available foam boards were placed in between the pallets with zeolite-filled pouches for ethylene absorption.

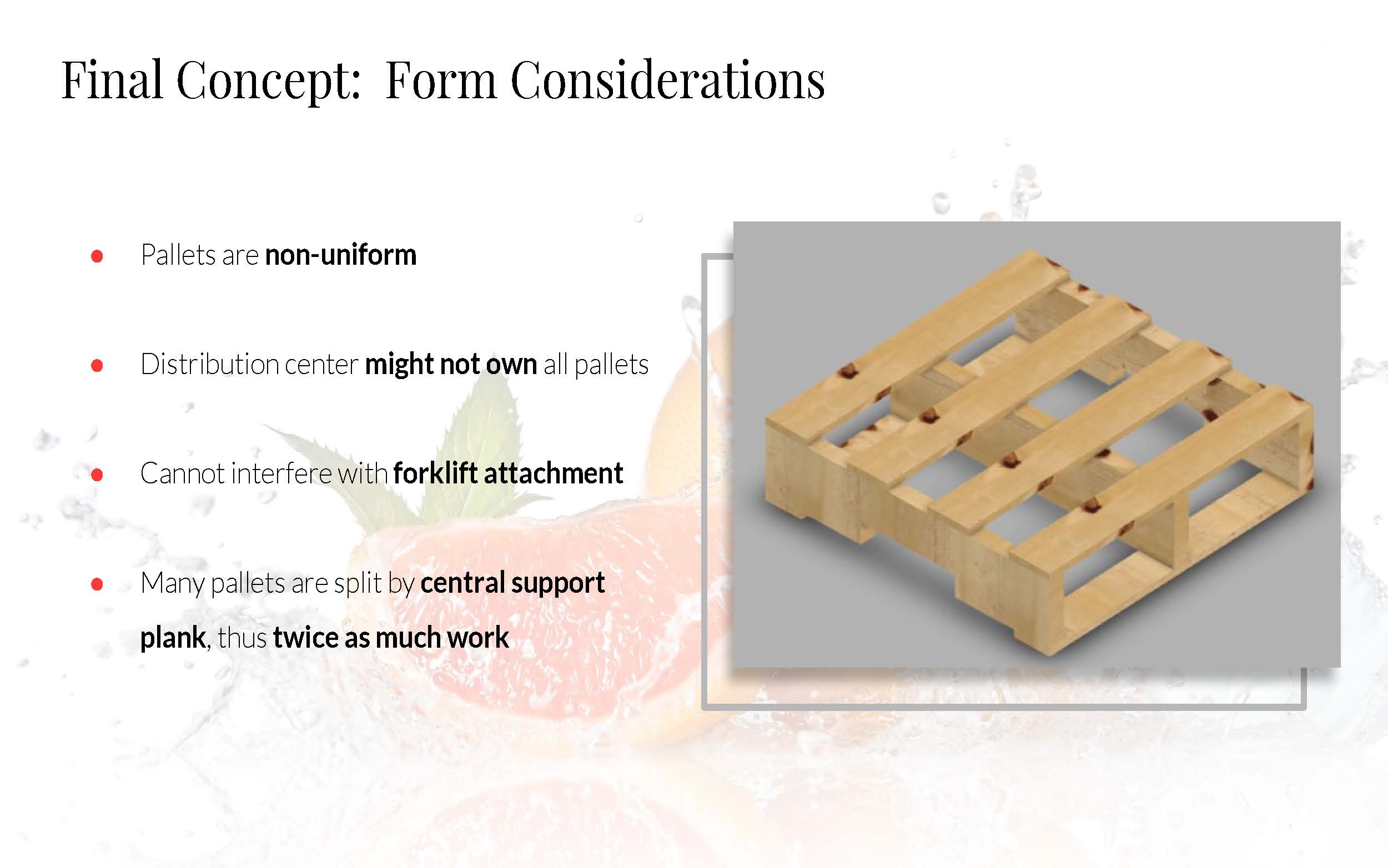

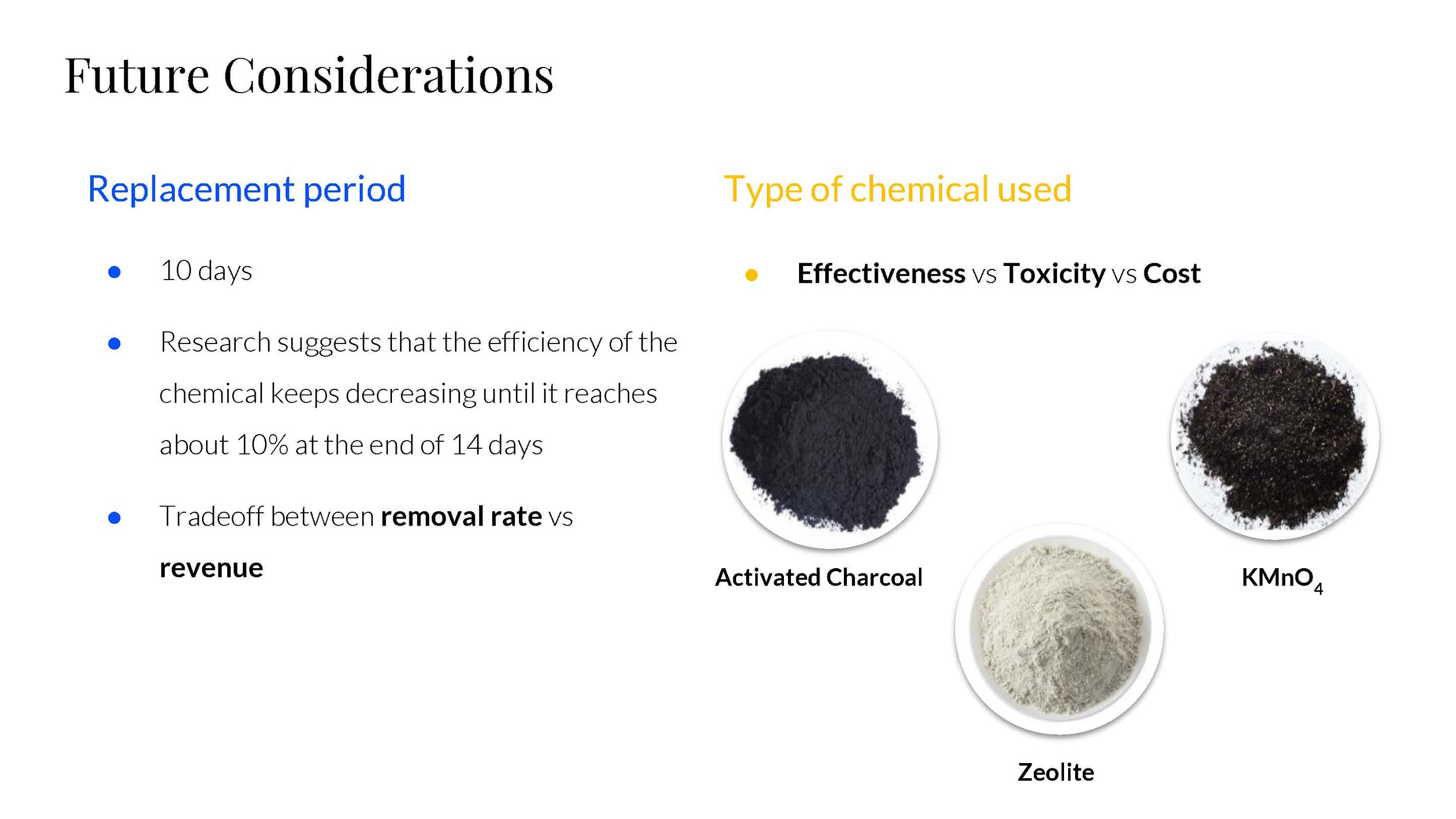

This experiment confirmed our concept of using zeolite to absorb ethylene so as to lengthen the ripening process of fast-moving produce. At this point, I pushed the team to ideate a more refined prototype. In our experiment, we glued zeolite packs beneath each pallet board, however, from our visits to various warehouses, we noticed cost concerns of introducing or even modifying any hardware, as the margin in food distribution is so thin. In addition, we were concerned about the interference with the forklifts when the pallets are moved.

The Design

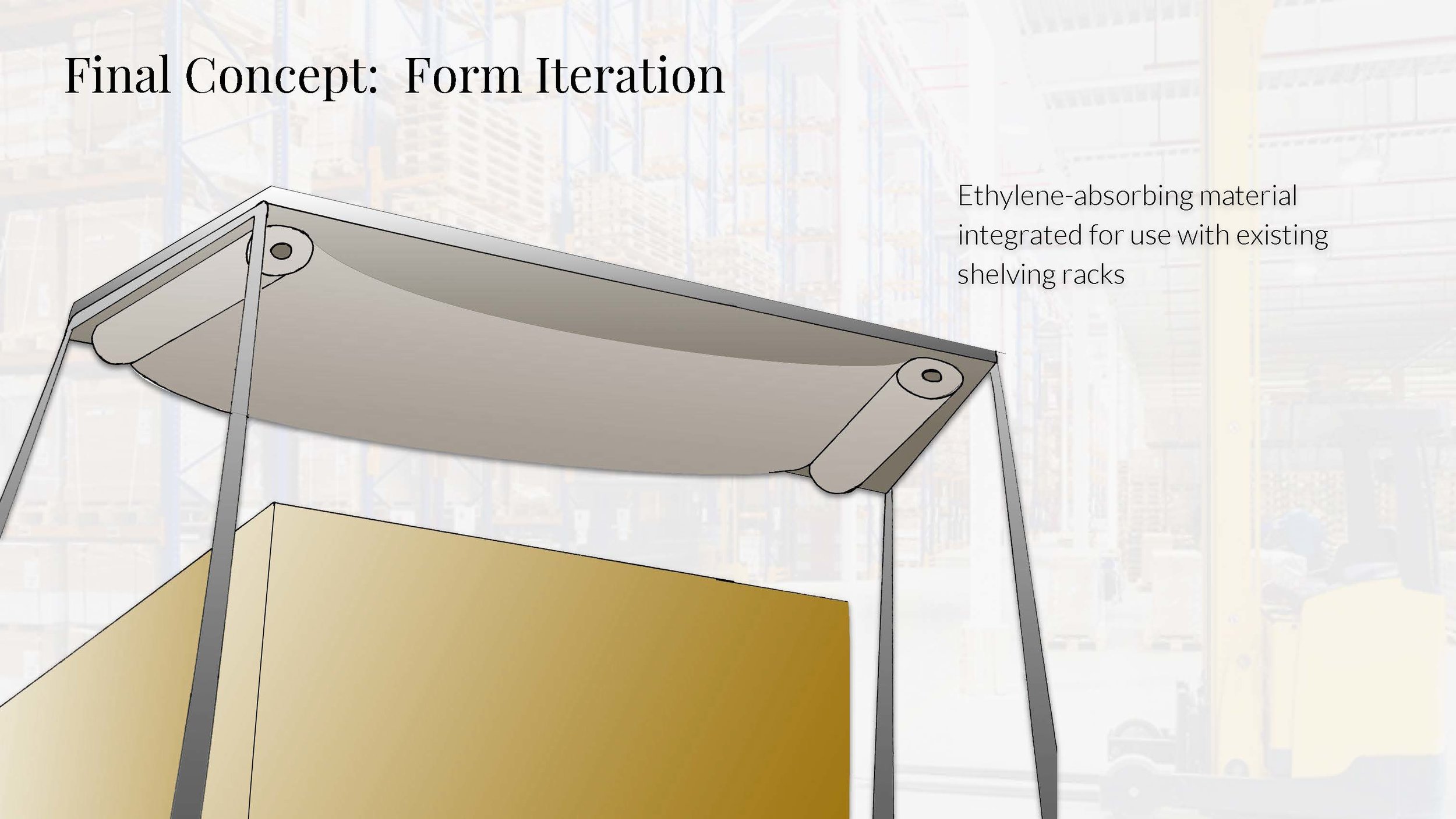

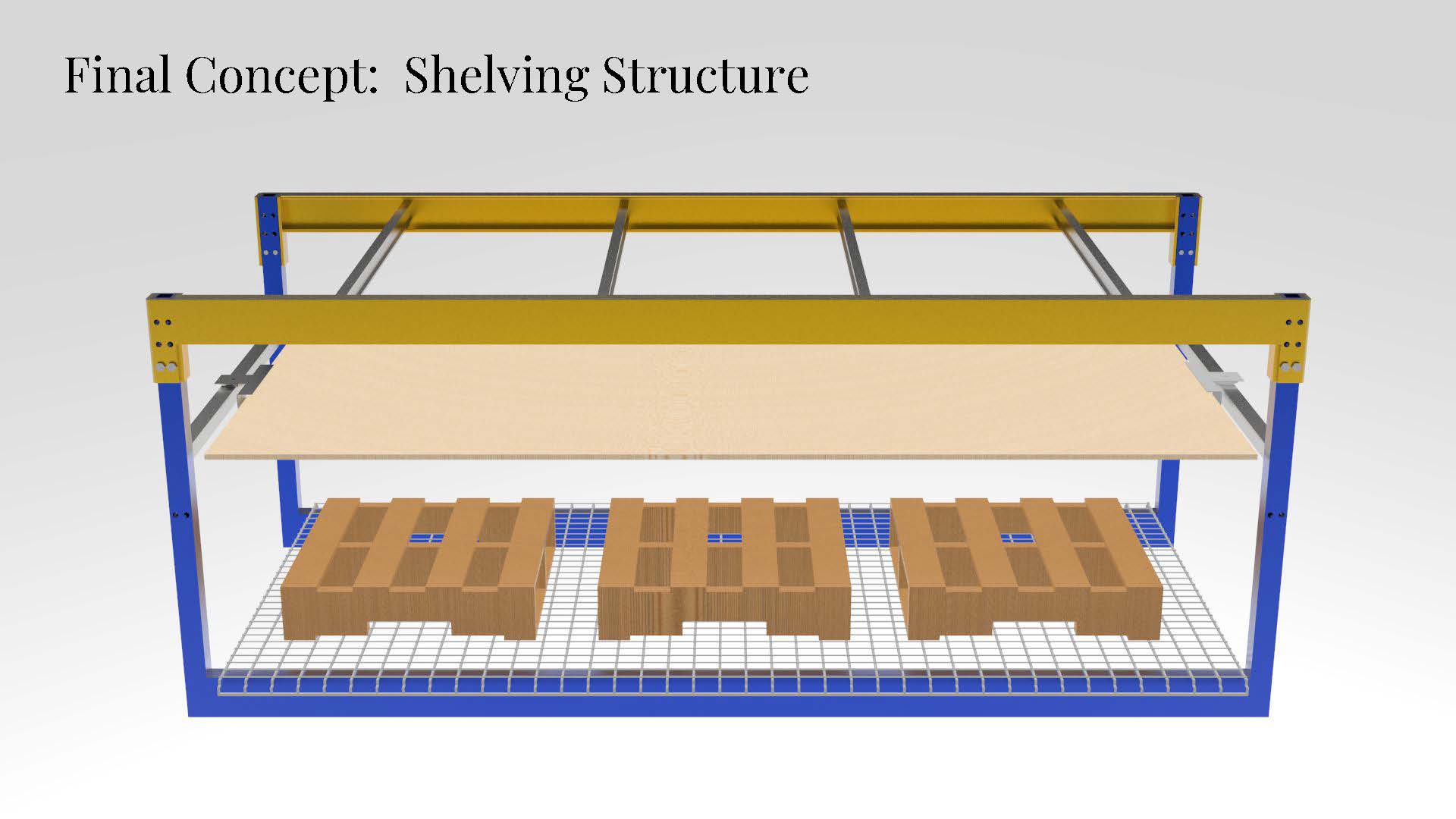

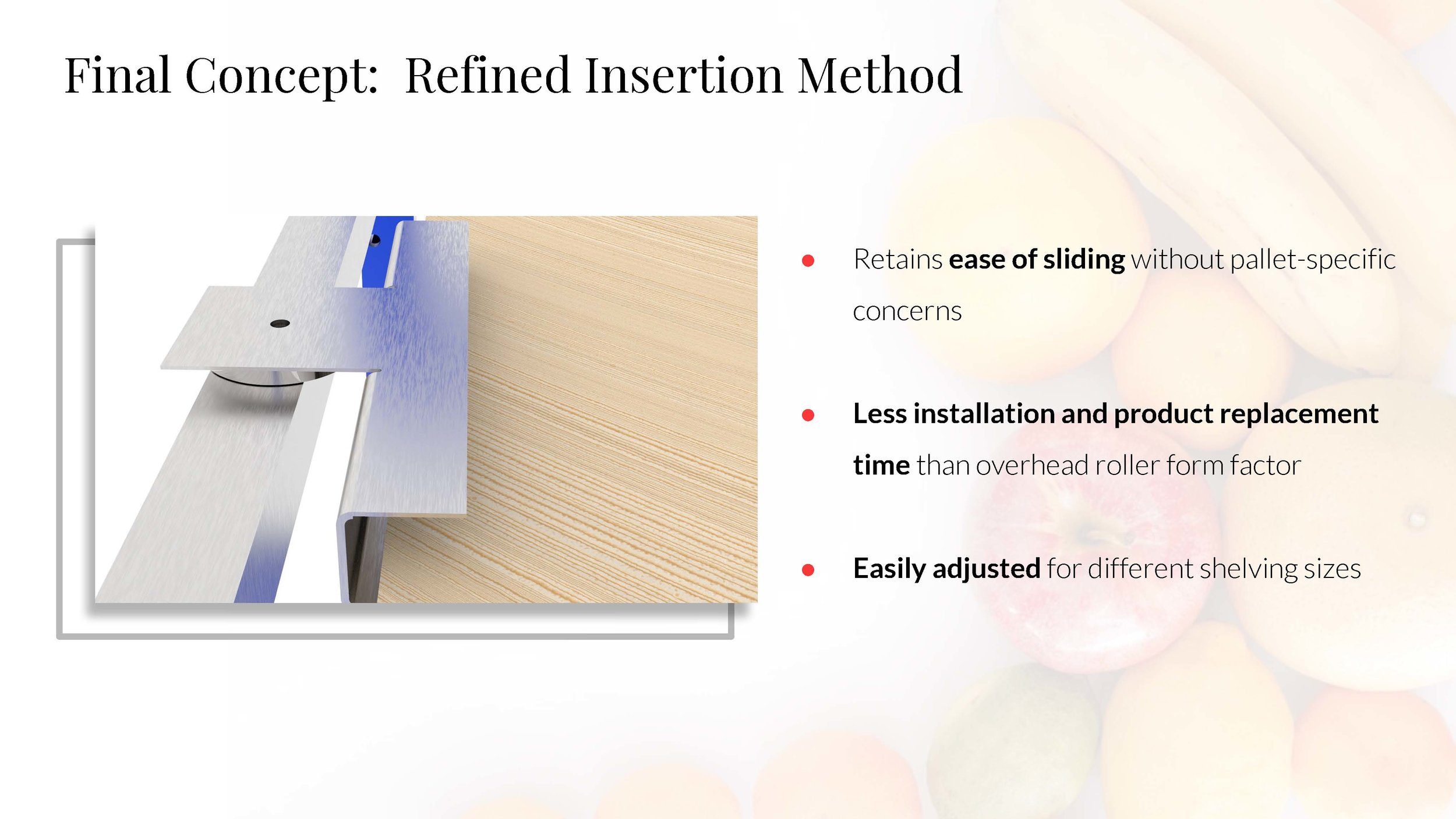

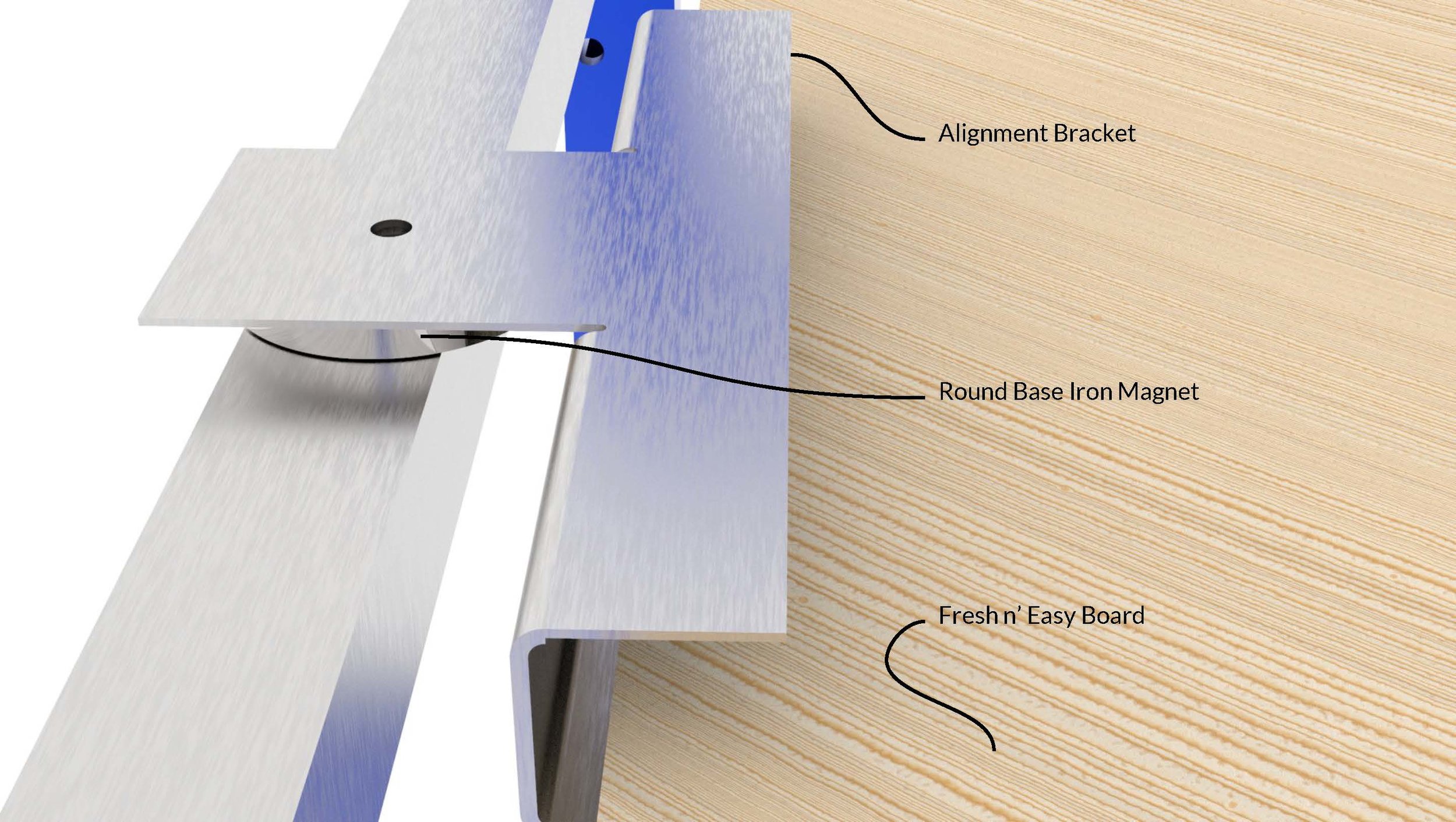

The experiment led us to choose the sliding board containing the zeolite, but in a form that uses the existing shelving racks for attachment points, as the solution to move forward.

By covering the body of the board with a thin layer of zeolite, we managed to maximize its surface area, thereby increasing the absorbency capacity. Cardboard was chosen as a cheap, recyclable, and sturdy backing for the board of 96’’ long to fit inside the standard shelving bay areas. A bracket structure made from fasteners, nuts, magnets, and alignment brackets allows for easy insertion of the cardboard. Magnets were chosen because they will allow the solution to be affixed to different brands of shelving structures, depending on the warehouse where they are to be installed. PLA, a cheap, porous fabric was combined with the cardboard to create a pocket for the zeolites. The edges of the PLA are glued to the board with a glue that is FDA-approved for non-contact in food storage settings.

Bill of Materials

| Part Number | Part | Material |

| 1 | Cardboard | Paper-based |

| 2 | Alignment Brackets | Stainless Steel - Grade 430 |

| 3 | Magnets | Iron |

| 4 | Plastic Cover | Polylactic Acid |

| 5 | Zeolite | Sodium Aluminosilicate |

| 6 | Titebond 3 Wood Glue | Aliphatic resins + Polyurethanes |

| 7 | Fasteners | Alloy steel |

| 8 | Nuts | Alloy steel |

Prototype Testing

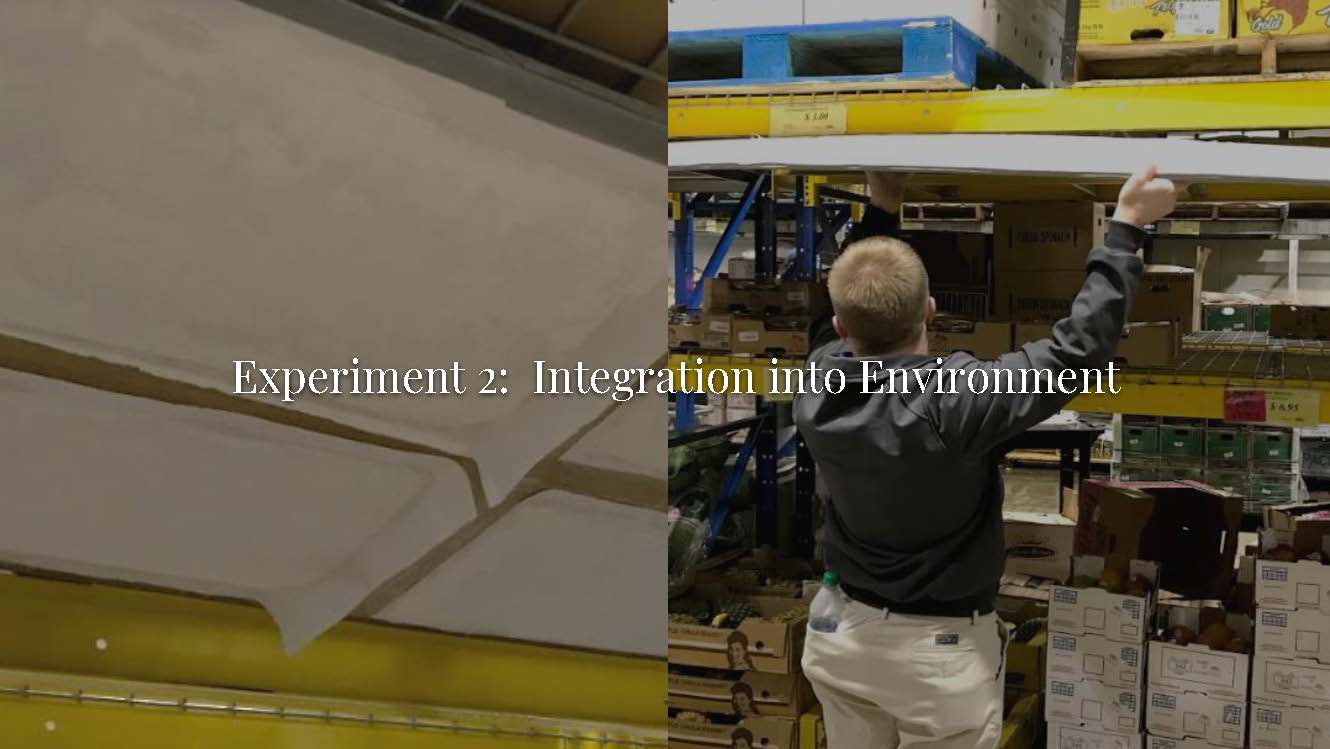

The team brought the physical prototype to Restaurant Depot to test its efficacy in an actual food storage environment. Ian McPherson, one of the produce section inventory managers, helped to coordinate the installation of our board. The low fidelity of our model, namely the use of non-rigid extensions to increase the length of the original board from 7 feet to 8 feet, made attaching the board to the guide rails too difficult. Instead, the board was mounted to the underside of the shelf ceiling and tied to the grates above with zip ties, as depicted in the figure below.

The board was placed in a pallet bay above 14 containers of strawberries. A control group of 8 containers was moved to a different area and stored at the same temperature. All containers were labeled to be sold within the next two days or else they would be thrown out.

After three days, the team returned and concluded that the products in every container in the control group had deteriorated to the point of being unsalable. However, 8 out of 14 of the containers underneath the Fresh n’ Easy board showed little or no blemishes, color changes, dehydration, or mold, and were determined to be salable or donation-worthy. To conclude, the Fresh n’ Easy board was able to recover 57% of strawberries by extending their shelf life by more than a day.

Thinking ahead

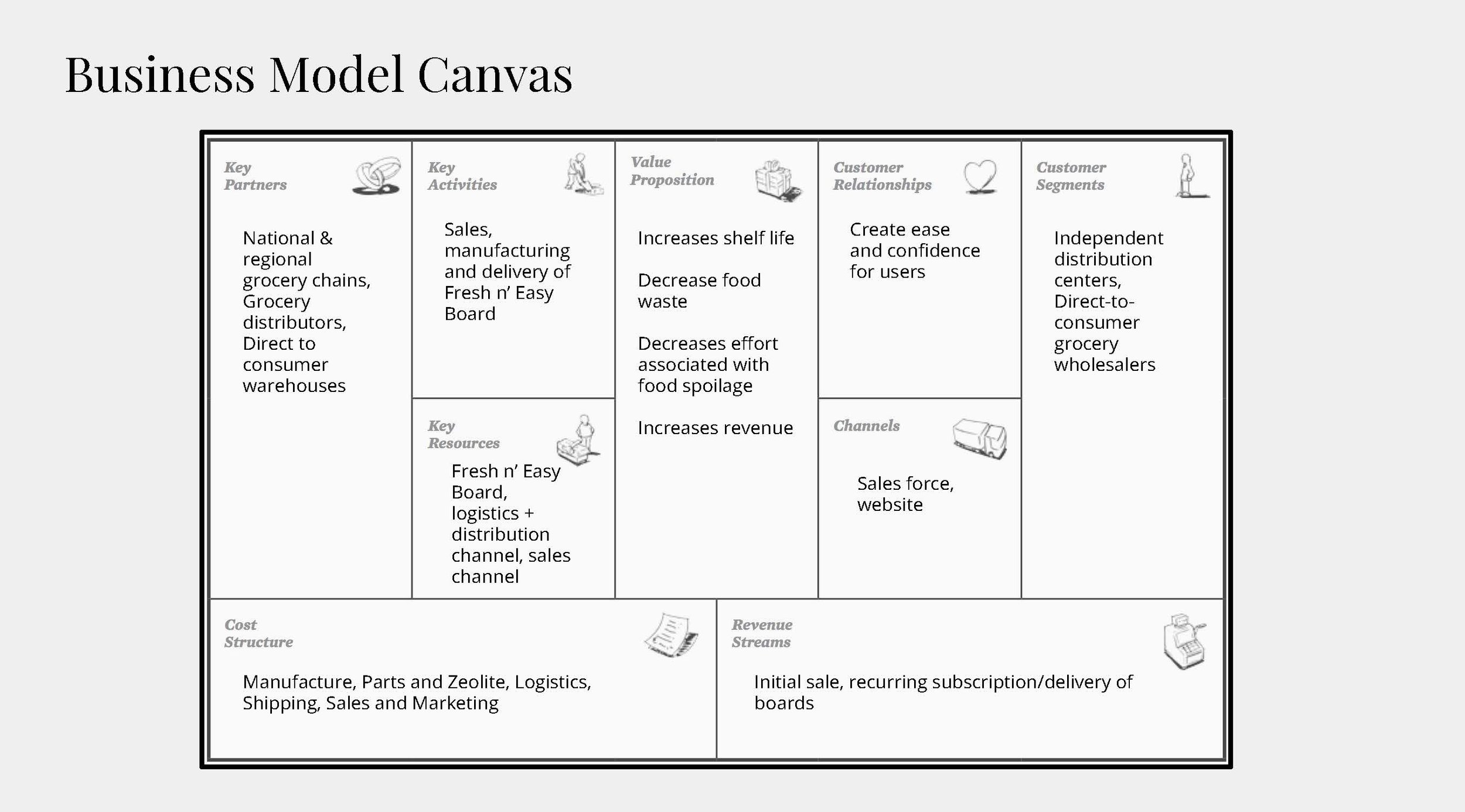

The food and fiber system is the largest manufacturing sub-sector in the US, which accounts for 12% of GDP and 17% of employment. There are approximately 900,000 food retail outlets in the US, ranging from grocery stores to national supermarket chains. In 2015, grocery store sales reached over $640bn. There is a large and well-established market for producing logistic solutions. The success of Fresh n’ Easy will depend on how to strategically define the target market and infiltrate large customers by understanding their purchasing procedures.

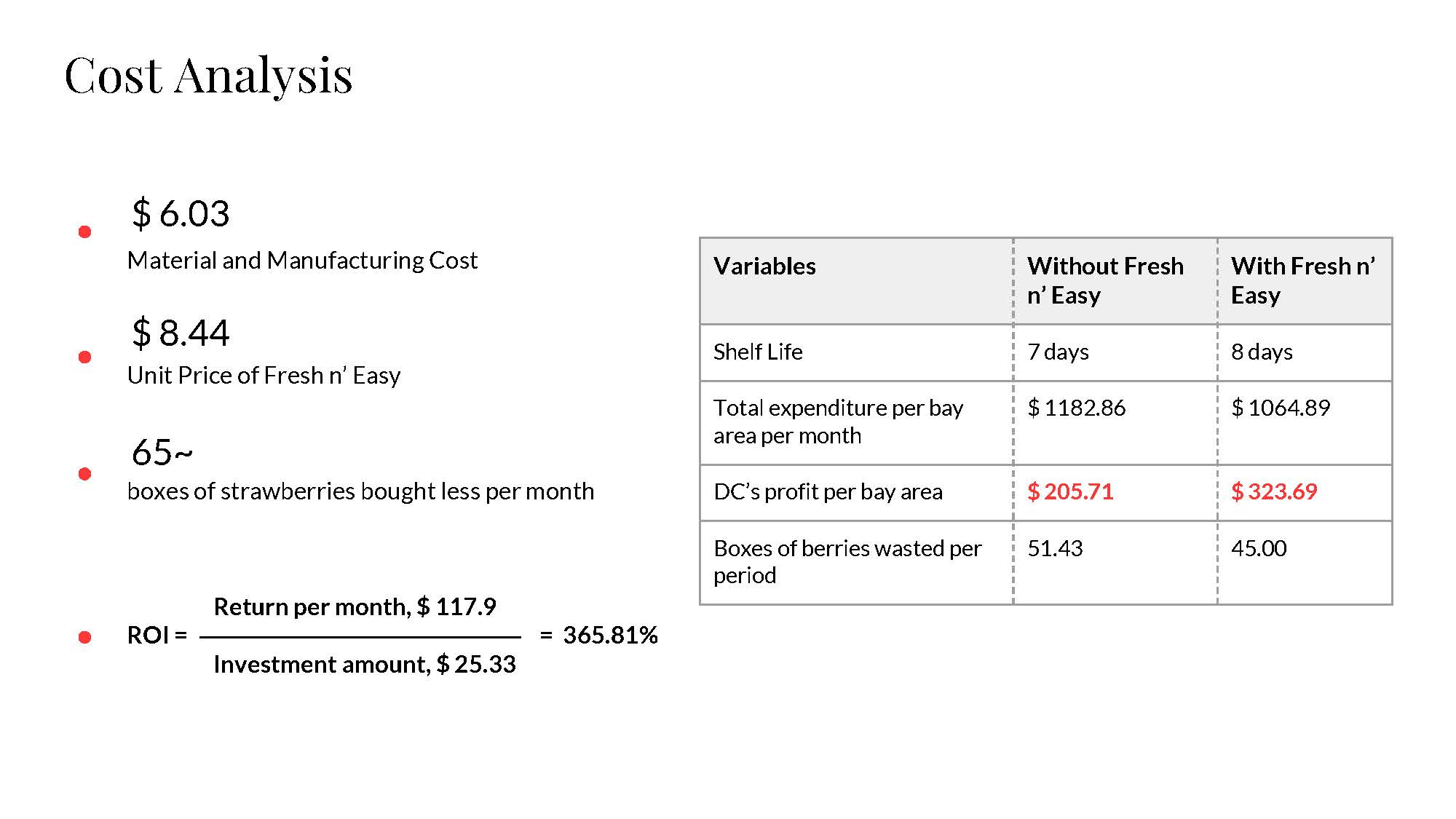

In the experiment, the team was able to extend the shelf life of strawberries by a day, or to roughly 114% of their initial shelf life. Additional value is generated because there is an overall decrease in food waste, the effort associated with handling, cleaning, and disposing of wasted food is decreased, and food quality and associated revenue are expected to increase.

The local Restaurant Depot estimated the value for our product to be around $100/month/bay, leading to a projected price for a month’s supply of Fresh n’ Easy boards for a single bay being $25.33. This generates an ROI for our customers of 365%.

By keeping the user involved during every step of the process, we made sure that the Fresh n’ Easy board is easy to use, lightweight, and quite readily integrated into the shelves of large distribution warehouses. With Fresh n’ Easy, distributors will be more confident optimizing the shelf life of their produce.

How long can food last? It just became longer now.

Other contributors:

Chelsie Corbett, Ben Fisher, Gokul Suryamurthy, Xi Zhang